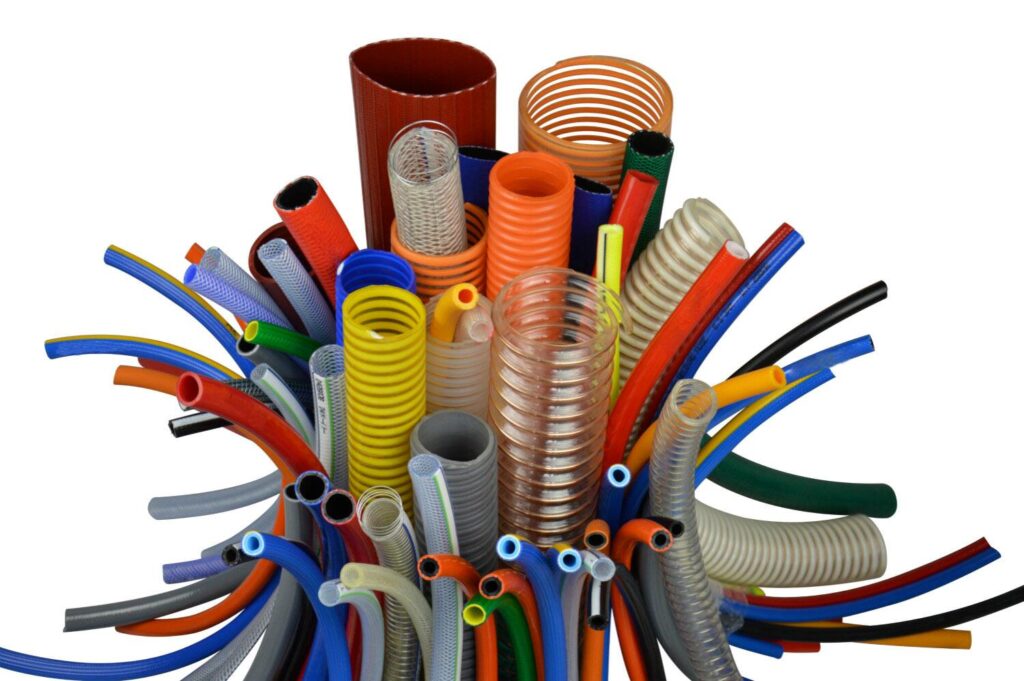

When it comes to selecting the right hose for industrial applications, the choice of material is crucial. Among the various options available, PVC (polyvinyl chloride) hoses have become increasingly popular due to their unique properties and versatility. However, they are not the only option. This article provides a comparative analysis of PVC HOSE Manufacturer against other common hose materials, such as rubber, polyurethane, and silicone, to help industries make informed decisions based on their specific needs.

1. Durability and Longevity

PVC Hoses:

- Durability: PVC hoses are known for their excellent resistance to abrasion, chemicals, and UV radiation, making them suitable for various industrial environments.

- Longevity: With proper maintenance, PVC hoses can last for several years, providing a cost-effective solution for many applications.

Rubber Hoses:

- Durability: Rubber hoses are also durable and offer good resistance to wear and tear, but they can be more susceptible to UV degradation compared to PVC.

- Longevity: Rubber hoses typically have a shorter lifespan than PVC hoses, especially when exposed to harsh environmental conditions.

Polyurethane Hoses:

- Durability: Polyurethane hoses are highly resistant to abrasion and kinking, making them ideal for rugged applications.

- Longevity: They often outlast rubber hoses but may not match the longevity of high-quality PVC hoses in certain conditions.

Silicone Hoses:

- Durability: Silicone hoses are flexible and resistant to extreme temperatures but can be more prone to wear over time compared to PVC.

- Longevity: Silicone hoses generally have a long lifespan, particularly in high-temperature applications.

2. Flexibility and Handling

PVC Hoses:

- Flexibility: PVC hoses are moderately flexible, allowing for ease of handling and installation. However, they can become less flexible in cold temperatures.

- Handling: They are lightweight, making them easy to transport and maneuver.

Rubber Hoses:

- Flexibility: Rubber hoses are highly flexible, making them ideal for applications requiring frequent movement or bending.

- Handling: While heavier than PVC hoses, they can withstand high pressures and are often preferred for heavy-duty applications.

Polyurethane Hoses:

- Flexibility: Polyurethane hoses are known for their exceptional flexibility and ability to return to their original shape after bending.

- Handling: They are lightweight and easy to handle, making them suitable for various industrial applications.

Silicone Hoses:

- Flexibility: Silicone hoses offer excellent flexibility, allowing for easy routing in tight spaces.

- Handling: They are lightweight and can maintain their shape under high temperatures.

3. Chemical Resistance

PVC Hoses:

- Chemical Resistance: PVC hoses have good chemical resistance, making them suitable for many industrial applications involving acids, bases, and certain solvents.

- Limitations: However, they may not be suitable for certain aggressive chemicals, such as ketones and aromatic hydrocarbons.

Rubber Hoses:

- Chemical Resistance: Rubber hoses vary in chemical resistance based on the type of rubber used. Some types, like nitrile rubber, offer excellent resistance to oils and fuels.

- Limitations: They may not be suitable for all chemicals, and specific rubber formulations are required for certain applications.

Polyurethane Hoses:

- Chemical Resistance: Polyurethane hoses offer good resistance to a wide range of chemicals, including oils and solvents.

- Limitations: They may not withstand some harsh chemicals, requiring careful selection based on the application.

Silicone Hoses:

- Chemical Resistance: Silicone hoses provide moderate chemical resistance and are suitable for food-grade applications due to their non-reactive nature.

- Limitations: They may not be ideal for all chemical applications, particularly those involving aggressive solvents.

4. Temperature Tolerance

PVC Hoses:

- Temperature Tolerance: PVC hoses can typically handle temperatures up to 140°F (60°C) but may lose flexibility in colder temperatures.

- Applications: They are suitable for many general industrial applications but may not perform well in extreme heat.

Rubber Hoses:

- Temperature Tolerance: Rubber hoses can withstand higher temperatures, typically ranging from -40°F to 212°F (-40°C to 100°C), depending on the rubber type.

- Applications: They are often preferred in applications involving steam or high-temperature fluids.

Polyurethane Hoses:

- Temperature Tolerance: Polyurethane hoses can handle a range of temperatures, often from -40°F to 180°F (-40°C to 82°C).

- Applications: Their flexibility at lower temperatures makes them suitable for cold environments.

Silicone Hoses:

- Temperature Tolerance: Silicone hoses excel in extreme temperature applications, withstanding temperatures from -100°F to 500°F (-73°C to 260°C).

- Applications: They are ideal for high-temperature applications in automotive and industrial processes.

5. Cost Considerations

PVC Hoses:

- Cost: PVC hoses are generally more affordable than many alternatives, making them a cost-effective choice for various applications.

- Value: Their durability and longevity contribute to a lower total cost of ownership.

Rubber Hoses:

- Cost: Rubber hoses can be more expensive than PVC hoses, particularly those designed for specialized applications.

- Value: While they offer excellent performance, the higher initial investment may not be justified for all users.

Polyurethane Hoses:

- Cost: Polyurethane hoses are often priced similarly to or slightly higher than PVC hoses, depending on the specific application.

- Value: Their durability and flexibility can make them a valuable investment for certain industries.

Silicone Hoses:

- Cost: Silicone hoses tend to be more expensive due to their specialized applications and material properties.

- Value: The high-temperature tolerance and flexibility can justify the higher cost for specific uses.

Conclusion: Making the Right Choice

Selecting the right hose material for industrial applications depends on various factors, including durability, flexibility, chemical resistance, temperature tolerance, and cost. PVC HOSE Manufacturer offer a balanced combination of these characteristics, making them suitable for a wide range of applications.

However, other materials such as rubber, polyurethane, and silicone also have their unique advantages and should be considered based on specific needs and environmental conditions. By understanding the strengths and limitations of each material, industries can make informed decisions that enhance operational efficiency and reduce costs.